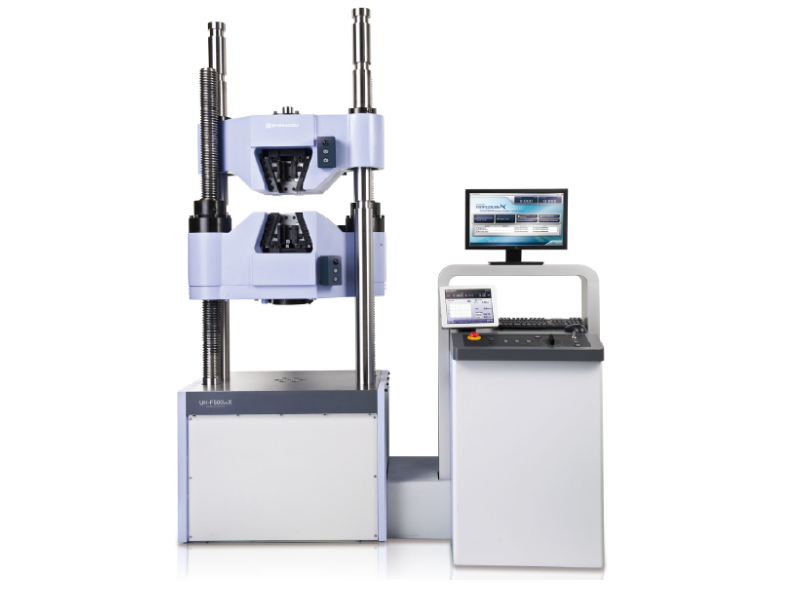

UH-200kNX

Technical Specifications

| - Max capacity | : 200 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 200/100/40/20/10/4 kN | |

| - Tensile test | Max. grip span (mm) | : 800 |

| Grip face for rod specimens (mm) | : ø8 to 40, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 35, 1 type (50 in width) | |

| - Compression test | Max. compression plate span (mm) | : 720 |

| Compression plate size (mm) | : ø100 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 500 |

| Support diameter × width (mm) | : 30 × 130 | |

| Punch tip radius (mm) | : 15 | |

| Punch width (mm) | : 130 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 80/100 max. |

| Drive motor | Servo valve | : 1.5 kW |

| - Ram stroke | (mm) | : 200 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 315/380 |

| Drive motor | : 400W | |

| - Column span | (mm) | : 500 |

| - Effective table dimensions (W × D) | (mm) | : 500 × 500 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 4 kVA |

| Hybrid | : 6.5 kVA | |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 30 A |

| - Testing machine size | Loading unit (mm) | : 780 × 500 × 2000 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 900 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | : Computer-controlled electro-hydraulic hybrid system | |

| - Force measurement | Method | : Cylinder internal pressure measurement with high-precision |

| pressure cell | ||

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-300kNX

Technical Specifications

| - Max capacity | : 300 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 300/150/60/30/15/6 kN | |

| - Tensile test | Max. grip span (mm) | : 800 |

| Grip face for rod specimens (mm) | : ø8 to 40, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 35, 1 type (50 in width) | |

| - Compression test | Max. compression plate span (mm) | : 720 |

| Compression plate size (mm) | : ø100 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 500 |

| Support diameter × width (mm) | : 30 × 130 | |

| Punch tip radius (mm) | : 15 | |

| Punch width (mm) | : 130 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 80/100 max. |

| Drive motor | Servo valve | : 1.5 kW |

| - Ram stroke | (mm) | : 200 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 315/380 |

| Drive motor | : 400W | |

| - Column span | (mm) | : 500 |

| - Effective table dimensions (W × D) | (mm) | : 500 × 500 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 4 kVA |

| Hybrid | : 6.5 kVA | |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 30 A |

| - Testing machine size | Loading unit (mm) | : 780 × 500 × 2000 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 900 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | : Computer-controlled electro-hydraulic hybrid system | |

| - Force measurement | Method | : Cylinder internal pressure measurement with high-precision |

| pressure cell | ||

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UHF-300kNX

Technical Specifications

| - Max capacity | : 300 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 300/150/60/30/15/6 kN | |

| - Tensile test | Max. grip span (mm) | : 800 |

| Grip face for rod specimens (mm) | : ø8 to 25 ø25 to 40 (option) |

|

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 20 20 to 40 (50 in width) |

|

| - Compression test | Max. compression plate span (mm) | : 720 |

| Compression plate size (mm) | : ø100 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 500 |

| Support diameter × width (mm) | : 30 × 130 | |

| Punch tip radius (mm) | : 15 | |

| Punch width (mm) | : 130 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 80/100 max. |

| Drive motor | Servo valve | : 1.5 kW |

| - Ram stroke | (mm) | : 200 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 380/450 |

| Drive motor | : Hydraulic motor | |

| - Column span | (mm) | : 500 |

| - Effective table dimensions (W × D) | (mm) | : 500 × 500 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 5.5 Kva |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 30 A |

| - Testing machine size | Loading unit (mm) | : 870 × 520 × 2300 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 1500 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | : Computer-controlled electro-hydraulic hybrid system | |

| - Force measurement | Method | : Cylinder internal pressure measurement with high-precision |

| pressure cell | ||

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-500kNX

Technical Specifications

| - Max capacity | : 500 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 500/250/100/50/25/10 kN | |

| - Tensile test | Max. grip span (mm) | : 900 |

| Grip face for rod specimens (mm) | :ø12 to 50, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 45, 1 type (60 in width) | |

| - Compression test | Max. compression plate span (mm) | : 800 |

| Compression plate size (mm) | : ø120 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 600 |

| Support diameter × width (mm) | : 50 × 160 | |

| Punch tip radius (mm) | : 25 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 65/80 max. |

| Drive motor | Servo valve | : 1.5 kW |

| - Ram stroke | (mm) | : 250 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 375/450 |

| Drive motor | : 750 W | |

| - Column span | (mm) | : 650 |

| - Effective table dimensions (W × D) | (mm) | : 650 × 650 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 4.5 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 30 A |

| - Testing machine size | Loading unit (mm) | : 960 × 650 × 2400 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 1700 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | : Computer-controlled electro-hydraulic hybrid system | |

| - Force measurement | Method | : Cylinder internal pressure measurement with high-precision |

| pressure cell | ||

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UHF-500kNX

Technical Specifications

| - Max capacity | : 500 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 500/250/100/50/25/10 kN | |

| - Tensile test | Max. grip span (mm) | : 900 |

| Grip face for rod specimens (mm) | : ø12 to 30 ø30 to 50 (option) |

|

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 30 30 to 50 (60 in width) |

|

| - Compression test | Max. compression plate span (mm) | : 800 |

| Compression plate size (mm) | : ø120 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 600 |

| Support diameter × width (mm) | : 50 × 160 | |

| Punch tip radius (mm) | : 25 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 65/80 max. |

| Drive motor | Servo valve | : 1.5 kW |

| - Ram stroke | (mm) | : 250 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 210/250 |

| Drive motor | : Hydraulic motor | |

| - Column span | (mm) | : 650 |

| - Effective table dimensions (W × D) | (mm) | : 650 × 650 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 5.5 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 40 A |

| - Testing machine size | Loading unit (mm) | : 1060 × 700 × 2900 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 2600 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | : Computer-controlled electro-hydraulic hybrid system | |

| - Force measurement | Method | : Cylinder internal pressure measurement with high-precision |

| pressure cell | ||

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-600kNX

Technical Specifications

| - Max capacity | : 600 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 600/300/120/60/30/12 kN | |

| - Tensile test | Max. grip span (mm) | : 900 |

| Grip face for rod specimens (mm) | : ø12 to 50, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 45, 1 type (60 in width) | |

| - Compression test | Max. compression plate span (mm) | : 800 |

| Compression plate size (mm) | : ø120 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 600 |

| Support diameter × width (mm) | : 50 × 160 | |

| Punch tip radius (mm) | : 25 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 65/80 max. |

| Drive motor | Servo valve | : 1.5 kW |

| - Ram stroke | (mm) | : 250 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 375/450 |

| Drive motor | : 750W | |

| - Column span | (mm) | : 650 |

| - Effective table dimensions (W × D) | (mm) | : 650 × 650 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 4.5 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 30 A |

| - Testing machine size | Loading unit (mm) | : 960 × 650 × 2400 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 1700 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | stops test upon reaching limit setting value) Control | |

| - Force measurement | Method | automatic stop (When an excessive control deviation is |

| reached, the test automatically stops.) | ||

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-1000kNX

Technical Specifications

| - Max capacity | : 1000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 1000/500/200/100/50/20 Kn | |

| - Tensile test | Max. grip span (mm) | : 1000 |

| Grip face for rod specimens (mm) | : ø12 to 70, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 65, 1 type (70 in width) | |

| - Compression test | Max. compression plate span (mm) | : 900 |

| Compression plate size (mm) | : ø160 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 800 |

| Support diameter × width (mm) | : 50 × 160 | |

| Punch tip radius (mm) | : 25 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 50/70 max. |

| Drive motor | Servo valve | : 2.2 kW |

| - Ram stroke | (mm) | : 250 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 330/400 |

| Drive motor | : 1.5kW | |

| - Column span | (mm) | : 750 |

| - Effective table dimensions (W × D) | (mm) | : 750 × 750 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 6.5 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 40 A |

| - Testing machine size | Loading unit (mm) | : 1170 × 750 × 2800 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 3500 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UHF-1000kNX

Technical Specifications

| - Max capacity | : 1000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 1000/500/200/100/50/20 Kn | |

| - Tensile test | Max. grip span (mm) | : 1000 |

| Grip face for rod specimens (mm) | : ø12 to 40 ø40 to 70 (option) |

|

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 35 35 to 70 (70 in width) |

|

| - Compression test | Max. compression plate span (mm) | : 900 |

| Compression plate size (mm) | : ø160 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 800 |

| Support diameter × width (mm) | : 50 × 160 | |

| Punch tip radius (mm) | : 25 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 50/70 max. |

| Drive motor | Servo valve | : 2.2 kW |

| - Ram stroke | (mm) | : 250 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 160/200 |

| Drive motor | : Hydraulic motor | |

| - Column span | (mm) | : 750 |

| - Effective table dimensions (W × D) | (mm) | : 750 × 750 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 7 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 40 A |

| - Testing machine size | Loading unit (mm) | : 1320 × 800 × 3400 |

| (W × D × H) | Measurement controller (mm) | : 740 × 1000 × 1800 |

| - Testing machine weight | Loading unit (kg) | : 6000 |

| Measurement controller (kg) | : 110 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-2000kNX

Technical Specifications

| - Max capacity | : 2000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 2000/1000/400/200/100/40 kN | |

| - Tensile test | Max. grip span (mm) | : 1100 |

| Grip face for rod specimens (mm) | : ø20 to 90, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 85, 1 type (90 in width) | |

| - Compression test | Max. compression plate span (mm) | : 950 |

| Compression plate size (mm) | : ø220 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 900 |

| Support diameter × width (mm) | : 70 × 200 | |

| Punch tip radius (mm) | : 30, 40 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 40/50 max. |

| Drive motor | Servo valve | : 5.5 kW |

| - Ram stroke | (mm) | : 300 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 290/350 |

| Drive motor | : 1.5 kW | |

| - Column span | (mm) | : 750 |

| - Effective table dimensions (W × D) | (mm) | : 850 × 850 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 12 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 75 A |

| - Testing machine size | Loading unit (mm) | : 1560 × 920 × 3400 |

| (W × D × H) | Measurement controller (mm) | : 740 × 1000 × 1800 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UHF-2000kNX

Technical Specifications

| - Max capacity | : 2000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 2000/1000/400/200/100/40 kN | |

| - Tensile test | Max. grip span (mm) | : 1100 |

| Grip face for rod specimens (mm) | : ø20 to 55 ø55 to 90 (option) |

|

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 45 45 to 90 (90 in width) |

|

| - Compression test | Max. compression plate span (mm) | : 950 |

| Compression plate size (mm) | : ø220 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 900 |

| Support diameter × width (mm) | : 70 × 200 | |

| Punch tip radius (mm) | : 30, 40 | |

| Punch width (mm) | : 160 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 40/50 max. |

| Drive motor | Servo valve | : 5.5 kW |

| - Ram stroke | (mm) | : 300 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 290/350 |

| Drive motor | : 2.2 kW | |

| - Column span | (mm) | : 850 |

| - Effective table dimensions (W × D) | (mm) | : 850 × 850 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 15 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 100 A |

| - Testing machine size | Loading unit (mm) | : 1560 × 920 × 4500 |

| (W × D × H) | Measurement controller (mm) | : 740 × 1000 × 1800 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-3000kNX

Technical Specifications

| - Max capacity | : 3000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 3000/1500/600/300/150/60 kN | |

| - Tensile test | Max. grip span (mm) | : 1200 |

| Grip face for rod specimens (mm) | : ø20 to 110, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 105, 1 type (110 in width) | |

| - Compression test | Max. compression plate span (mm) | : 1000 |

| Compression plate size (mm) | : ø280 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 1000 |

| Support diameter × width (mm) | : 80 × 230 | |

| Punch tip radius (mm) | : 40, 50 | |

| Punch width (mm) | : 230 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 40/50 max. |

| Drive motor | Servo valve | : 5.5 kW |

| - Ram stroke | (mm) | : 300 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 290/350 |

| Drive motor | : 2.2 kW | |

| - Column span | (mm) | : 1000 |

| - Effective table dimensions (W × D) | (mm) | : 1000 × 1000 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 11 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : — |

| - Testing machine size | Loading unit (mm) | : 1860 × 1100 × 3970 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UHF-3000kNX

Technical Specifications

| - Max capacity | : 3000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 3000/1500/600/300/150/60 kN | |

| - Tensile test | Max. grip span (mm) | : 1200 |

| Grip face for rod specimens (mm) | : ø20 to 55 ø55 to 85 (option) |

|

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 55 55 to 110 (110 in width) |

|

| - Compression test | Max. compression plate span (mm) | : 1000 |

| Compression plate size (mm) | : ø280 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 1000 |

| Support diameter × width (mm) | : 80 × 230 | |

| Punch tip radius (mm) | : 40, 50 | |

| Punch width (mm) | : 230 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 40/50 max. |

| Drive motor | Servo valve | : 5.5 kW |

| - Ram stroke | (mm) | : 300 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 290/350 |

| Drive motor | : 3.7 kW | |

| - Column span | (mm) | : 1000 |

| - Effective table dimensions (W × D) | (mm) | : 1000 × 1000 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 15 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : — |

| - Testing machine size | Loading unit (mm) | : 1860 × 1100 × 5700 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UH-4000kNX

Technical Specifications

| - Max capacity | : 4000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 4000/2000/800/400/200/80 kN | |

| - Tensile test | Max. grip span (mm) | : 1400 |

| Grip face for rod specimens (mm) | : ø30 to 120, 1 type With liner | |

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 115, 1 type (120 in width) | |

| - Compression test | Max. compression plate span (mm) | : 1150 |

| Compression plate size (mm) | : ø300 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 1000 |

| Support diameter × width (mm) | : 80 × 250 | |

| Punch tip radius (mm) | : 40, 50 | |

| Punch width (mm) | : 250 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 40/50 max. |

| Drive motor | Servo valve | : 7.5 kW |

| - Ram stroke | (mm) | : 350 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 290/350 |

| Drive motor | : 3.7 kW | |

| - Column span | (mm) | : 1150 |

| - Effective table dimensions (W × D) | (mm) | : 1150 × 1150 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 16 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : — |

| - Testing machine size | Loading unit (mm) | : 2200 × 1400 × 4800 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||

UHF-4000kNX

Technical Specifications

| - Max capacity | : 4000 kN | |

| - Force range | : Rangeless | |

| - Analog Indicator | : 4000/2000/800/400/200/80 kN | |

| - Tensile test | Max. grip span (mm) | : 1400 |

| Grip face for rod specimens (mm) | : ø20 to 60 ø60 to 90 (option) ø90 to 120 (option |

|

| Grip face for flat plate specimens (option) *3 (mm) | : 0 to 60 60 to 120 (120 in width) |

|

| - Compression test | Max. compression plate span (mm) | : 1150 |

| Compression plate size (mm) | : ø300 | |

| - Transverse/bending test (option) *4 | Max. support span (mm) | : 1000 |

| Support diameter × width (mm) | : 80 × 250 | |

| Punch tip radius (mm) | : 40, 50 | |

| Punch width (mm) | : 250 | |

| - Loading speed (50/60 Hz) (mm/min)*1 | Servo valve | : 40/50 max. |

| Drive motor | Servo valve | : 7.5 kW |

| - Ram stroke | (mm) | : 350 |

| - Crosshead elevation speed (50/60 Hz) | (Approx.) (mm) | : 290/350 |

| Drive motor | : 5.5 kW | |

| - Column span | (mm) | : 1150 |

| - Effective table dimensions (W × D) | (mm) | : 1150 × 1150 |

| - Power supply capacity (Approx.) (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : 18 kVA |

| - Recommended breaker capacity (3-phase, 200 V, 50 Hz/200 to 220 V, 60 Hz) |

Servo valve | : — |

| - Testing machine size | Loading unit (mm) | : 2200 × 1400 × 5900 |

| (W × D × H) | Measurement controller (mm) | : 740 × 800 × 1800 |

Measurement Controller Standard Specifications

| - Loading method | automatic stop (When an excessive control deviation is | |

| - Force measurement | Method | reached, the test automatically stops.) |

| Precision standard type | : Within ±1.0 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 1, ISO 7500/1 Class 1, and | ||

| ASTM E4)*1 | ||

| High-precision type (option) | : Within ±0.5 % of indicated value | |

| (when the force is 1/1 to 1/250 of rated value) | ||

| (Conforming to JIS B7721 Class 0.5, ISO 7500/1 Class 0.5, | ||

| and ASTM E4)*1 | ||

| Magnification | : Rangeless | |

| - Force display | Operation unit | : Digital display Min. display resolution: 1/200,000 |

| (300 kN/3000 kN: 1/240,000) | ||

| Analog force indicator*2 | : Analog display Scale plate diameter: 450 mm; | |

| Min. scale: 1/1000 (300 kN/3000 kN: 1/600) | ||

| - Stroke measurement display | : Measurement with optical encoder; digital display | |

| (resolution: 0.01 mm) | ||

| - Automatic load control | Method | : Fully closed-loop automatic load control |

| Test control functions | : Single test control, Cycle test control (triangular wave, | |

| trapezoidal wave), Stress test control, Strain test control, | ||

| Stroke speed 3-step switching control, Concrete test | ||

| control (compression, bending, cleavage tests) | ||

| Range | : Ram stroke control Speed range: 0.1 mm/min to | |

| max. loading speed* | ||

| Control range: Ram return point to max. ram stroke | ||

| Test force control Speed range: 0.2 % to 500 % full-scale/min | ||

| Control range: 0.4 % to 100 % of full-scale force | ||

| Strain control Speed range: 0.1 % to 80 %/min | ||

| Control range: 5 % to 100 % of full-scale elongation | ||

| - Input/output interface | : External analog input: 2 CH; External analog output: 2 CH | |

| External digital input: 2 CH (optional); Internal amplifiers | ||

| possible: 2 ports | ||

| Analog recorder (optional) output, USB function | ||

| (for computer) / Host (for USB memory) interface, | ||

| and Dataletty (optional) output | ||

| - Standard function | : Auto-test force-strain control (with auto-tuning), Test force | |

| auto-zero, Test force auto-calibration, Break detecting | ||

| (break sensitivity, break level, break peak level, and high | ||

| sensitivity), Auto-return, Arbitrary stroke speed setting, | ||

| Stroke speed preset, Cycle count, Stress value display, | ||

| Displacement meter value display, PEAK/BREAK value | ||

| display, Test condition files (100 files), Japanese/English | ||

| display, S–S curve display, Specimen protection, Current | ||

| speed display, and Manual load control | ||

| - Safety devices | : Overload automatic stop (When the test force value | |

| exceeds 102 % of the full-scale value, the loading pump | ||

| automatically stops.) Software limit detection (automatically | ||

| stops test upon reaching limit setting value) Control | ||

| automatic stop (When an excessive control deviation is | ||

| reached, the test automatically stops.) | ||